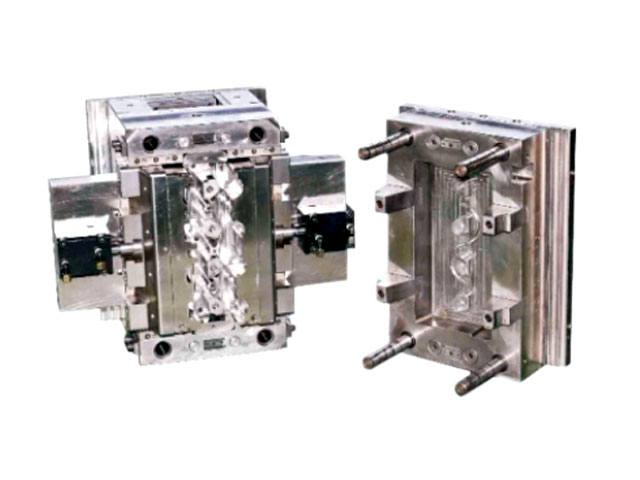

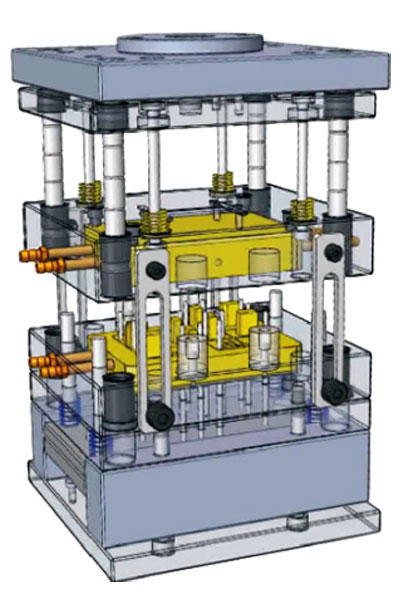

Aim Plast is your reliable partner for tool- and mould making. Specialised in the production of injection-moulding and die-casting tools, our many years of experience and high-quality, comprehensive service are truly impressive.

Design, Development & Tool Room :

lndigenization & customization of intricate injection molded plastics components is our strength. With this approach our tool room is equipped with all essential ultra modern machines along with design facilities. We offer a complete solution to customer which includes - Product design assistance, Part process feasibility study, tool design, tool making & finished product supply

Facilities:

With built-up area of 8000 Sq.ft our state-of-the-art Moulding shop consists of comprehensive range of 16 Injection moulding machines from 15 Ton to 150 Ton capacity. This also includes special purpose vertical Injection Moulding machines with rotary table as well as single sliding bed suitable for insert moulding, Terminal moulding & Over moulding applications.

This compliments our expertise in meeting the ever challenging quality demands of these types of components in the industry

Infrastructure

Why to Choose Aim Plast

Every tool manufactured in house is tailor-made. Our know-how and modern machinery enable us to offer a broad range of services – including the following procedures for precision grinding technology:

CNC Milling

CNC controlled 3 axis vertical machining center

Turning

Cycle-controlled, Ø 100 x 500mm

Surface grinding

Table 600 x 300mm

Measuring

Mitutoyo digital calipers profile projector

Spark Erosion

EDM Spark Erision (JOMERS) Size - 750 x 500mm

CAD/CAM DESIGN & Devlopment

CAD/CAM

High quality, high tolerance precision plastic moulds are delivered with a quick turnaround. We provide great customer service, backed by technical expertise, at great value prices.

Our experienced designers can design Moulds in 2D and 3D according to your specific requirements. Thanks to the latest CAD workstations and expertise in machining of intricate profiles of the moulds with high precision with short delivery times.

Unlike many of our competitors – we’re able to totally guarantee the quality of the tooling. We always value this fact hence Aim Plast has become the trusted customer’s choice.